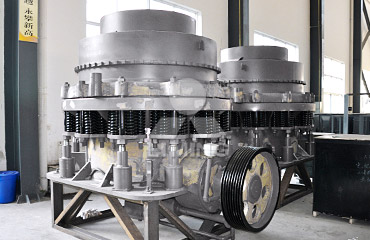

The CS Cone Crusher is mainly composed of the frame, the fixed cone assembly, the moving cone assembly, the spring mechanism, the bowl type shaft frame and the transmission; the auxiliary part is composed of the electrical system, the thin oil lubrication system and the hydraulic chamber cleaning system.

When working, the electric motor drives the eccentric sleeve through the triangle belt, large pulley, transmission shaft, small bevel gear and large bevel gear, and the axis of the crushing cone is forced by the eccentric sleeve to do rotational oscillation, which makes the surface of the crushing wall close to and sometimes leave the surface of the rolling molar wall, so that the material is continuously crushed by impact, extrusion and bending in the ring crushing cavity composed of the fixed cone and the moving cone. After repeated extrusion, impact and bending, the material is crushed to the required size and discharged through the lower part.

Add a review

Here you can submit your requirements for equipment, processing materials and output of the project, and our relevant engineers will respond as soon as possible