Saltpeter, also known as flame nitrate and potassium saltpeter, has a glassy luster like other minerals, white, colorless and grey color, mainly used as pastel and colorful pigments, in addition, it can also be used as raw materials for glass and food preservatives.

The processing of saltpeter needs to go through two stages of crushing and milling, and milling as one of the important processes of saltpeter can make the saltpeter grinding very fine, saltpeter mill plays an important role in the milling operation of saltpeter.

The industrial use of saltpeter: saltpeter is often used to make black powder, fuse, glass, matches, fireworks, also used as fertilizer (potash, nitrogen fertilizer) and laboratory analysis reagents. Saltpeter can be used to formulate peacock green glaze, can also be used as five colors, pastel pigments.

Industrial mannite has polyhydric mannite, ten hydrous mannite, seven hydrous mannite, etc. They are mainly used in the chemical industry to make anhydrous sodium sulfate, alkali sulfide, effervescent alkali, barium sulfate and other chemical raw materials. They are widely used in many industries such as chemical industry, light industry, textile, building materials, pharmaceutical manufacturing and so on.

Horse-teeth nitrate is a large mannite containing crystals of crystalline water, colorless and easily soluble in water. It is widely used in glass manufacturing industry, alkali industry, leather manufacturing industry and so on.

Xuanming powder is produced by weathering and drying of manganese nitrate, also known as weathering nitrate. Park Nitrate, Mangnite, Xuanming powder has the same effect. The main components are sodium sulfate and trace magnesium sulfate, sodium chloride, calcium sulfate and so on. Xuanming powder is often used to make pure Chinese medicine powder.

Sodium nitrite (edible nitrate) is a food additive, commonly used in pickled meat food. Sodium nitrite is poisonous, 0.2 grams to 0.5 grams of human consumption may appear poisoning symptoms, if a one-time accidental consumption of 3 grams, may cause death.

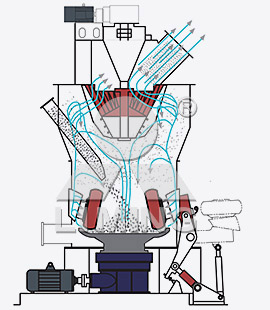

LM Vertical Mill can meet the demand of nitrate grinding, LM series vertical mill mainly consists of grinding roller assembly, grinding disk assembly, hydraulic station, transmission arm assembly, powder selector, main reducer, motor, body, main reducer lubrication station, hydraulic station, PLC electric control cabinet and other parts.

LM Vertical Roller Mill Working Illustration

When working, the main motor through the reducer to drive the mill rotating, while the hot air from the air inlet into the vertical mill body, the material from the mouth of the lower material falls in the middle of the mill, under the action of centrifugal force, the material from the middle of the mill to the edge of the uniform movement, through the mill on the mill rollers area, by the grinding roller milling, the large material is crushed directly, the fine material is crushed by the extrusion of the formation of the material bed for the inter-granular crushing. The crushed material continues to move to the edge of the mill until it is taken away by the strong airflow at the wind ring, and the larger particles fall back to the mill to continue crushing, the material in the airflow through the upper part of the separator, under the action of the rotor blade, the coarse particles are back to the mill for grinding, and the qualified fines come out of the mill with the airflow, and are collected by the collector of the system, and the collected powders are the products milled by the vertical mill. Mixed into the material, iron and other debris with the material movement to the edge of the grinding disk, due to their own weight and can not be blown up by the wind, fell to the mill cavity by the installation of the bottom of the grinding disk scraping plate scraped into the slag discharge port out of the machine.

If you are interested in our products please call us at 0086-371-67997088 or click Business Link Online We will be online 24 hours a day, welcome to call. Our customer service staff will provide you with detailed answers, thoughtful service, will be happy to provide you with product information and application knowledge, so that you can not only get valuable equipment, but also get our attentive service.