Coal powder is processed through the coal mill after the product of raw coal, particle size less than 0.5mm coal, commonly used in thermal power plants, metallurgy, chemical industry and boiler coal powder, today introduces the case of the coal powder project located in Gansu Dingxi system and the case of the coal powder preparation project in Hebei Wuan steel plant, take a look ~ If you have the need or questions, welcome to contact our online customer service staff or leave a message, we invite you to cooperate with you!

Case one:

Gansu Dingxi pulverized coal preparation project case: the customer is a well-known domestic pulverized coal boiler manufacturer, this project is to provide raw materials for municipal heating in Dingxi city. the EPC turnkey device is perfect, the operation efficiency is high, and in all aspects of the focus on environmental protection, the operating environment is clean.

Processing material: coal

Capacity: 45-55T/H

Feed size: ≦50mm (80%≦10mm)

Fineness of finished product: 200 mesh D85

Equipment Configuration: LM Vertical Roller Mill, MTW Euro Mill, 5X Euro Intelligent Mill, LUM Ultrafine Vertical Mill

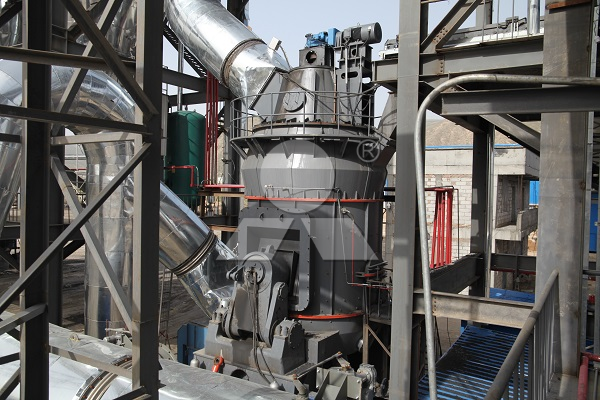

Site situation: The belt conveyor sends the raw coal to the system raw coal silo, and then it is fed into the LM2200M vertical coal mill by the closed quantitative coal feeder, and then after sorting, the coarse coal dust with unqualified fineness is regrinded, and the coal dust with qualified fineness is collected and then sent to the finished product silo through the discharge port for storage.

coal mills

Case two:

Hebei Wuan steel mill coal powder preparation project: this project is a steel mill coal powder preparation project in Hebei Wuan, configured with the main coal powder preparation equipment for the LM1500 Vertical Coal Mill, with a rated power of 600KW, and will be the integration of desulfurization, denitrification, dust removal devices installed, so that the coal powder boiler combustion efficiency increases, the output is increased, and the pollutant emissions are reduced, is the ideal equipment for the preparation of coal powder, desulfurization of the plant, cement, slag, and the realization of grinding. It is the ideal equipment for coal powder preparation, power plant desulfurization, cement and slag grinding.

Processing material: bituminous coal

Output: 18-22T/H

Fineness of finished products: 200 mesh = D80

Equipment Configuration: LM Vertical Roller Mill, MTW Euro Mill, 5X Euro Intelligent Mill, LUM Ultrafine Vertical Mill

Site situation: Raw coal is fed into two LM1500M vertical coal mills through closed quantitative coal feeder, meanwhile, hot air from heating furnace enters into the vertical coal mills from the air inlet under the pumping of the system fan, and after fully exchanging heat with the ground raw coal in the mills, it will bring up the coal dust to be sorted in the separator, and the coarse coal dust of unqualified fineness will fall back to the milling disk for grinding, and the coal dust of qualified fineness will enter into the airflow with the explosion-proof air box pulse dust collector. Explosion-proof air box pulse dust collector is collected, after collection of coal powder finished products through the discharge port and by the conveying device sent to the next link for use.

If you are interested in our products please call us at 0086-371-67997088 or click Business Link Online We will be online 24 hours a day, welcome to call. Our customer service staff will provide you with detailed answers, thoughtful service, will be happy to provide you with product information and application knowledge, so that you can not only get valuable equipment, but also get our attentive service.